News

PIAB Palletizing Solutions

Piab Palletizing Solutions

Piab offers a wide range of custom and standard End of Arm Tools (EOAT) for typical industrial palletizing and de-palletizing operations. All tools are designed to ensure safe operation, no goods are damaged, run with the highest efficiency, and that maintenance is simple and kept to a minimum. Below are the first of Piab’s palletizing solutions to be standardized and made available. Watch for future releases as you may find one that fits your needs.

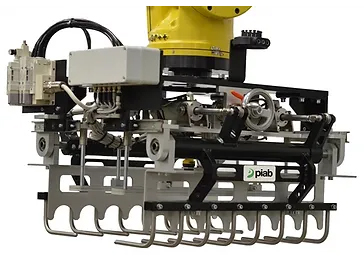

ABG Bag Gripper

Piab’s ABG palletizing solution is designed to ensure that no goods are damaged, operations are safe and run with the highest efficiency, and that maintenance is simple and kept to a minimum. This End of Arm Tool comes with a variety of options such as pallet handling, slip sheet systems and sensors.

- Heavy-duty rails and bearings with double seals and grease ports, less required maintenance

- Fast adjustment of bag sizes via hand wheel, lead screw, bearing blocks and shaft locks

- High-flow pneumatic solenoid valves for fast movement

- Reliable ultrasonic bag presence sensor

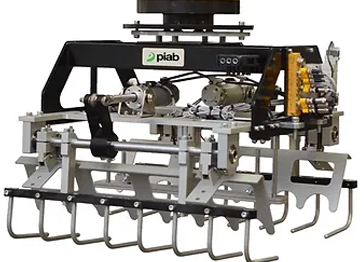

FBG Bag Gripper

The FBG palletizing solution from Piab allows you to quickly adjust the stainless-steel gripper fingers to accommodate changes in bag size. Simply adjust the width by loosening eight bolts and fit the tool to the new bag. Designed to ensure that goods are not damaged, this end of arm tool can accommodate a variety of requirements including pallet handling and slip sheet systems.

- Heavy-duty rails and bearings with double seals

- Simple bag width adjustment by loosening 8 bolts

- Solid stainless-steel Gripper Fingers with radiused ends to avoid damage to the bag

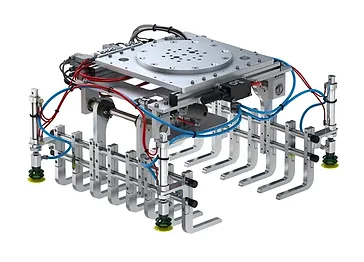

LBG-50 Bag Gripper

The LBG-50 is a pre-engineered solution which represents Piab’s gripper technology for palletizing. While “Lightweight” refers to the gripper’s refined design, the LBG-50’s performance is anything but that. It easily lifts up to 50 kg / 110 lb sacks off of a conveyor and securely places them on a pallet in any desired pattern. If slip sheets are required, the LBG-50 can be upgraded with a handling system using Piab’s Duraflex® suction cups and COAX® technology.

- Bag dimensions up to 495 x 650 x 215 mm and up to 50 kg weight

- Lifts bags and sacks of any standard material such as paper, plastic, non-woven, and cloth

- Vacuum based slip sheet handling upgrade available

- Adjustable width and finger positions for perfect adaptation to both conveyor and sacks, active top clamp plate ensures a secure vertical grip

- Lightweight tool design in aluminum, maximizing the robot’s payload

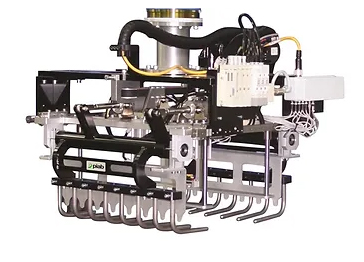

SBG Bag Gripper

Piab’s SBG palletizing solution features heavy-duty rails and bearings with double seals and grease ports to reduce maintenance requirements. Designed to run with the highest efficiency, this end of arm tool comes with a variety of options including slip sheet systems, sensors, and pallet handling.

- Solid stainless-steel Gripper Fingers with radiused ends to avoid damage to the bag

- Heavy-duty rails and bearings with double seals and grease ports for less required maintenance

- Gearbox with pulley / belt drive system

- Adjustable Decking Plates are independent of the Gripper Fingers enabling a very tight loading pattern and squared-up bags

- Top-mounted bag clamps to secure the bag, allows high speed traversing, faster load times