Parker PCH Portal

PCH Network Portal

What is PCH Network Portal?

PCH Network Portal is a new approach to ethernet communication modules that redefines and revolutionizes machine I/O architecture (inputs and outputs). As an ethernet node with IO-Link master capability that supports multiple Industrial Ethernet communication protocols (EtherNet/IP, PROFINET, Modbus TCP and EtherCAT), the PCH Network Portal can communicate with many industrial controllers used in the automation industry. It is classified as a Cyber Physical System for its ability to communicate across machinery while offering maximum function integration, simplicity of use, and significant architecture cost reductions.

The PCH Network Portal was engineered for flexible manufacturing applications where machine changes are common, PLC’s are not always accessible, and where obstacles on the plant floor make setup, configuration and troubleshooting time consuming. The PCH Network Portal was engineered with configurable I/O with true PNP / NPN circuitry switching and the open protocol, IO-Link, on each port for easy machine design changes. With built-in configurable IO-Link master ports all packed into an IP65, weld splatter resistant housing, the PCH Network Portal can future-proof your machine to changes in your network architecture. Built-in programming functions such as debounce timers and time stamped rolling 40 errors, warnings and events logs make troubleshooting and integration easy, even for an unseasoned programmer.

When commissioning or troubleshooting, multiple interfaces can be used in conjunction with a PLC, such as the embedded webpage and the PC based PCH Portal Configuration Tool. Configuration and troubleshooting can be done via a laptop, tablet, or phone via a secure and lockable Bluetooth connection, providing remote control of the PCH Network Portal which enhances safety by allowing commissioning and troubleshooting outside of the safety area of the machine; especially when dealing with robot controllers or end effector tooling.

NOTE: When PCH is owned by a PLC or another master controller configuration and forcing of valves, inputs and outputs is limited.

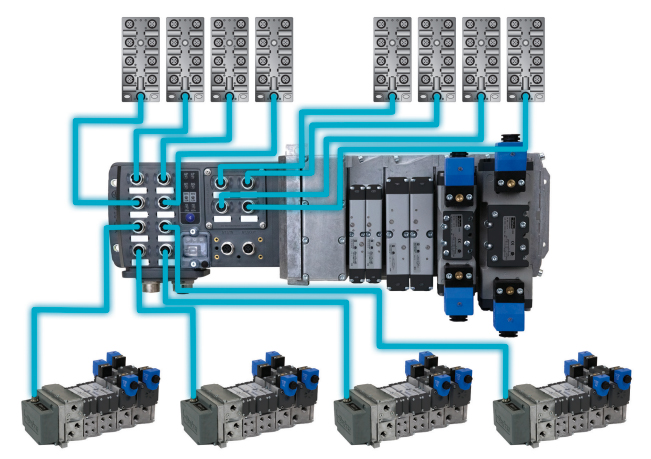

Assembled with Parker’s H ISO Universal Manifold, the PCH Network Portal can serve as your go-to ethernet node to control pneumatic valves across the entire flow spectrum.

Architecture Savings, Dramatic Versatility

The modularity of the PCH Network Portal can significantly optimize the layout and architecture of a machine offering significant cost reductions in machine design, during integration or simply through rapid troubleshooting and maintenance benefits. Reducing architecture complexity, increasing compatibility and interchangeability of connected devices, together with an ease of set-up and programming, allows the PCH Network Portal to achieve incredible savings in machinery design.

Utilizing the PCH Network Portal allows applications the flexibility of expanded I/O. Furthermore, taking advantage of the PCH Network Portal’s IO-Link master capabilities can dramatically increase the available I/O on a machine. IO-Link opens the door to low cost integration of devices like RFID read head integration, smart lights, distribution blocks, and inductive couplers all in one fixed form factor. This integrated flexibility eliminates the need for expensive ethernet masters, and cabling. As your application grows, the PCH Network Portal can adapt to meet many needs in the automation world.

The example above shows the PCH Network Portal expanded to 128 inputs via 8 IO-Link discrete I/O blocks, 4 additional valve manifolds via IO-Link each expandable to 24 valves. These connections are made with the non-proprietary and open protocol IO-Link, which uses standard M12 cables. The PCH Network Portal provides the opportunity to control an entire cell or line by with just one ethernet connection

Flexible Design, Value Redefined

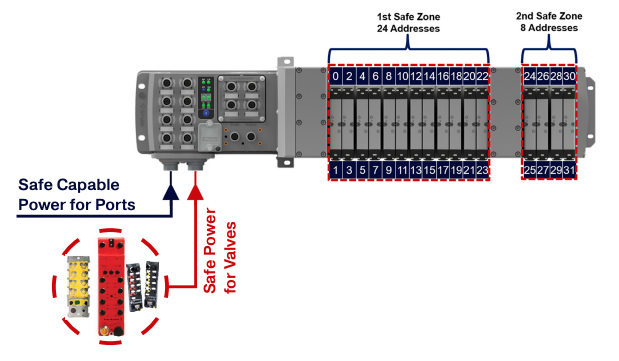

Safe power enhances the security of important connections such as light curtains that require OSSD test pulsing following machinery directives to achieve safety conformance. The illustration below shows the flexibility offered by the PCH Network Portal when separated into two isolated safe power zones using the S4 or S5 power options. The left power connector (‘Safe Power Capable for Ports’) provides safe capable power to the PCH Network Portal I/O auxiliary ports. The right power connector (‘Safe Power for Valves’) provides 2 safe power zones for attached pneumatic valves via isolated pins and safe grounds. The first safe power zone covers the first 24 valve solenoids of the pneumatic manifold. The second safe power zone covers the final 8 valve solenoids of the pneumatic manifold. NOTE: Intermediate air supply with expansion too 25th address is required. These safe power zones can be used to implement safe process lines and safe machines all in one compact and powerful solution.

Design Your System

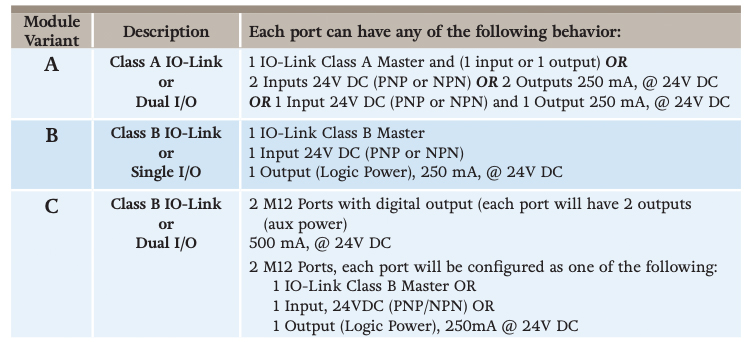

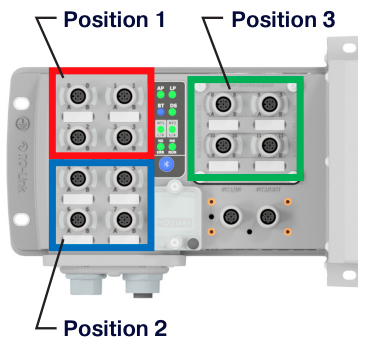

The PCH Network Portal can accommodate up to three module variants (A, B, and C), each offering uniquely customizable ports. Once you select your module those ports become fully configurable as IO-Link A or IO-Link B master ports or configurable PNP or NPN digital I/O ports. This makes changes on the machine flexible without having to purchase new components.